What’s the difference between a mockup and a prototype? Do all projects need both, and how can you tell? Find your answers here as we explore the best practices for rapid prototyping, mockup-making, and fast manufacturing.

Making a mockup can be a crucial part of the product development process. It helps teams focus on the primary features before digging into finer details. Mockups provide critical insights for engineers to examine, discuss, evaluate, and enhance. However, these benefits of mockups also confuse some. What’s the difference between a mockup and a prototype?

Mockups and prototypes are two fundamental tools for modern manufacturing. Product designers use both to proactively develop products, test innovations, and demonstrate features. Meanwhile, each process offers unique insights and is used for different purposes. They also provide different levels of detail, depending on your team’s requirements.

Do all projects need mockups and prototypes for excellent results? How can you tell when designs require additional processing? This blog will explore the subtle variations between a mockup and a prototype to help you determine the best approach. We’ll also discuss the benefits of rapid prototyping after the mockup phase and learn tips for making the most of both. Let’s get to it.

Table of Contents

Mockup Examples in Manufacturing

Prototype Examples in Manufacturing

Mockup VS Prototype: Which One Should You Choose?

Fashion or Function: That Is the Question

How to Choose Between a Mockup and a Prototype

Tips for Making the Most of Mockups and Rapid Prototyping

#2. Consider Additive Manufacturing

#3. Get a Rapid Prototyping Service Quote

10 Things to Ask a Manufacturer Before Submitting a Mockup for Rapid Prototyping

What Is a Mockup?

Is a mockup the same as a prototype? The quick answer is no. Many product developers use mockups to communicate concepts and share rough drafts. This helps teams understand various design aspects, including the look and purpose of an innovative solution.

“Mockups are static visual representations of an unfinished idea.”

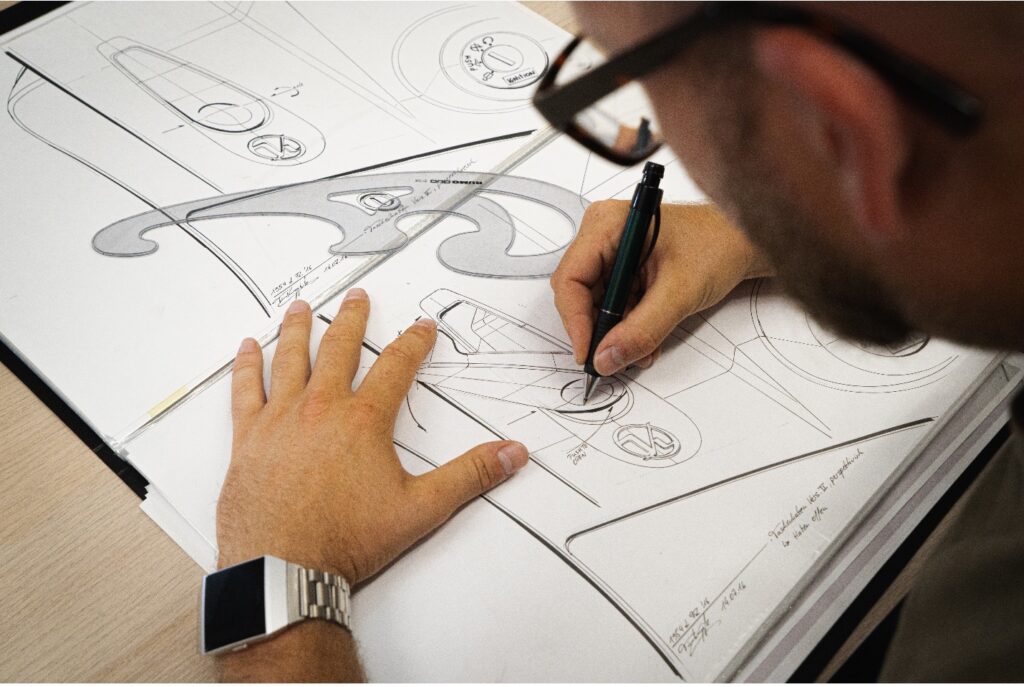

Making a mockup in the beginning stages of product development can help ensure everyone is on the same page before moving forward. The two-dimensional models demonstrate crucial elements to engineers, machinists, executives, investors, and stakeholders.

We offer fast, high-quality, tailored PROTOTYPING solutions for leading companies in a wide range of industries.

superior Rapid PROTOTYPING

Manufacturing mockups are especially important because they help engineering teams remove design flaws and risks. Experts can quickly iterate concepts, share information, receive feedback, and implement changes ahead of time. Then the rapid prototyping phase begins with streamlined blueprints featuring the most critical components.

Mockup Examples in Manufacturing

Every industry requires different mockup types to demonstrate ideas and share information. For example, a mockup for a digital product would not include the same tools or strategies as a manufacturing mockup. It might consist of digital elements, but it’s still not a prototype.

Knowing what to expect can help you get the most out of your investment. Check out these mockup examples in manufacturing:

- Two-dimensional drawings

- Digital sketches

- Dummies

- Adapted replicas

- Detailed descriptions

Experienced manufacturers can help take projects from concept to creation – from mockup to prototype to production. If your team needs a closer view of various elements, rapid prototyping is likely your next best step because a simple mockup might not fit the bill.

Pros and Cons of Mockups

Making a mockup for later manufacturing can help streamline product development projects, but what about the downsides? Could a prototype work better for some applications? Let’s explore the pros and cons of mockups for a better understanding:

Pros

- Increases productivity.

- Boosts product quality.

- Less manufacturing waste.

- Fast communication.

- Low-tech collaboration.

Cons

- Not interactive.

- Low fidelity.

- Lacking details.

- Prolongs lead times.

- Increases production costs.

“Mockup-making is not free and can take time despite being straightforward.”

Developing products from a vague concept requires clear communication and, often, several iterations. Talk to a rapid prototyping expert for more information and recommendations.

What Is a Prototype?

How do prototypes differ from mockups, and what are some examples of prototyping in manufacturing? Are there any pros or cons to consider? This section will answer those questions to help position your team for the most efficient outcome. It will also help you understand the difference between a mockup and a prototype.

Rapid prototyping allows engineers to communicate concepts, test functionality, and demonstrate features before manufacturing. Like a mockup, prototypes provide a look at the overall design for pre-production enhancements. However, this approach is much more detailed and interactive.

“Mockup-making can suffice in many instances, but it doesn’t go far enough for manufacturers requiring precision and sustainability.”

Teams use prototypes to test user flows, adjust functional elements, and gather feedback from relevant sources. You can’t get that from a quick, two-dimensional sketch.

Prototype Examples in Manufacturing

Manufacturers using rapid prototyping to ensure top-quality products depend on timeliness and precision. Rapid prototyping offers both and can handle more complex geometrical renderings for due diligence. This is a significant benefit for companies following ISO standards and strict production guidelines.

Here are some examples of common prototypes used in modern manufacturing:

- Wireframes

- 3D printed models

- Full-scale templates

- Digital diagrams

Rapid prototyping is an excellent source of information for savvy manufacturers. However, the process also has several disadvantages that teams should consider. Let’s explore those next.

Pros and Cons of Prototypes

Prototyping innovations can be tricky, and there is no perfect answer when troubleshooting products. That said, RP has multiple benefits and some drawbacks you should know.

Pros

- Increases productivity.

- Boosts product quality.

- Ensures regulatory compliance.

- Lessons manufacturing waste.

- Enables meaningful collaboration.

- Creates templates for mass production.

Cons

- Prolongs lead times.

- Increases manufacturing costs.

- Requires multiple iterations.

Rapid prototyping gives you interactive models to help engineers and stakeholders understand the design. Unlike a mockup, a prototype zooms in on the details to elicit practical feedback for implementation and distribution.

Mockup VS Prototype: Which One Should You Choose?

Choosing between a mockup and a prototype is essential unless you plan to use both. It’s also a crucial consideration because each process requires different tools. Teams must structure their approach to accommodate the necessary techniques or risk wasting time, money, and resources.

Fashion or Function: That Is the Question

A prototype’s primary purpose is to demonstrate how a design functions, even if the design is part of a multi-faceted project. Meanwhile, a mockup shows how a design looks before it becomes part of the bigger picture. Manufacturers should choose between fashion and function when deciding which operation to pursue.

Mockups render low-fidelity models using tools such as Photoshop, Illustrator, or Sketch. Some teams might also submit hand-drawn examples of design concepts for further processing. This helps developers determine whether they’re headed in the right direction or need more feedback.

Prototypes provide that feedback and more. Rapid prototyping helps teams quickly test product utilities and amenities relative to the overall concept. These early models focus on various specified tasks to give stakeholders a sense of the finished version.

How to Choose Between a Mockup and a Prototype

It can be challenging to choose a starting point for product development and manufacturing. How do you know if you have a feasible design? When do you begin production once you’ve locked in the features? Your team can help, but answer these questions first:

- How much detail do you need?

- Who is the product model for?

- Do you have enough time for the required processes?

- How will you manage the feedback?

- Are both operations within your budget?

- Have you received a rapid prototyping quote?

Talk to experts in rapid prototyping to determine how close your mockup is to manufacturing. Then learn how to make the most of your efforts.

Tips for Making the Most of Mockups and Rapid Prototyping

Making the most of your time and money is essential regardless of which fast fabrication method you choose. However, certain strategies can help you enjoy the benefits of both processes without breaking the bank or unnecessarily prolong lead times. Try these four tips to strengthen your approach.

#1. Add the Details in Layers

Begin with a simple mockup of the overall concept. Include aesthetic details and sweeping functionality information but save the complexities for later. You can add different elements as you receive helpful feedback from team members. This helps remove confusion, hastens productivity, and encourages collaboration before the real work begins.

FACT: Many manufacturers can assist engineers with transforming rough sketches into digital models for rapid prototyping, 3D printing, and machining.

#2. Consider Additive Manufacturing

Additive manufacturing (AM) allows product developers to quickly build, examine, and improve elements of an unfinished design. It’s also an excellent option for less complex products requiring little machining. AM saves materials and lets teams stop production mid-process for efficient troubleshooting.

FACT: AM is often called 3D printing because it applies materials in precise layers based on a blueprint.

#3. Get a Rapid Prototyping Service Quote

Building from a mockup requires different fees and time commitments than rapid prototyping. Each project is unique, so it’s impossible to determine costs and other expectations without a consultation. Talk to your team about their goals, and then share your objectives with professionals. Seek RP service quotes to compare prices and get the best deal.

FACT: Services could cost more if you begin with a simple mockup or static sketch.

#4. Ask the Right Questions

Prepare for multiple steps and reiterations while developing innovative products from a mockup. Consider rapid prototyping to help illustrate complex concepts and build precise inventories. Lead the competition with knowledge and experience by interviewing manufacturers during the quoting phase. Determine your boundaries and expectations, then ask questions that give the information needed.

FACT: Service consultations are generally free and can revolve around your schedule.

10 Things to Ask a Manufacturer Before Submitting a Mockup for Rapid Prototyping

It’s time to turn your mockup concept into a prototype reality. Arrive ready with these ten questions in your back pocket:

- How long does rapid prototyping take on a project like this?

- What are the variables my team should consider?

- Are there any materials we should seek or avoid?

- Which elements are required for turning a mockup into a prototype?

- What technologies do you use to ensure top-quality outcomes?

- How do I share information or receive feedback with your approach?

- What happens if I’m displeased with the first prototype?

- Is there such a thing as a high-fidelity mockup?

- What’s the difference between rapid prototyping and 3D printing?

- Do you have any examples of past work that I can see?

Conclusion

In summary, mockups and prototypes are not the same despite being used for similar purposes. A mockup is a simple iteration of a complex design used for quick demonstrations, communication, and confirmation. These low-fidelity renderings are perfect for showing the overall features of a product before further manufacturing.

Conversely, prototypes allow teams to demonstrate features and communicate feedback but on a much deeper level. These detailed three-dimensional models are best for testing user flows, interactions, and functionality. Both are essential to modern manufacturing, so speak to an expert for more information.

About the Author

About the Author

James Murphy is the founder and CEO of HLH Rapid – a hybrid CNC machine shop fusing Western service and quality with Eurasian industry influences for over 14 years. His advanced enterprise uncovers cost-effective rapid injection molding techniques to remain unmatched by industry competitors. Murphy’s full-service fabrication and manufacturing methods span six dedicated zones, from 3D printing and vacuum casting to sheet metal prototyping and project management. His expertise also includes high-efficiency machining within strict yet volatile markets.

Murphy earned an MBA after becoming inspired by his father’s hands-on craftsmanship. As a budding entrepreneur, he taught English and studied Chinese to pursue pioneering objectives. His groundbreaking approach helps build the future by providing well-rounded manufacturing services to innovative Western businesses. When he’s not offering upscale RP and CNC, James enjoys art-house movies, Thai boxing, and spending time with his growing family.

Visit HLHRapid.com for an instant quote on rapid prototyping services.

This Post Has One Comment

thanks for info