Computer-aided engineering has revolutionized manufacturing with digital fabrication tools like rapid prototyping and 3D printing. Consider these real-world applications, benefits, and capabilities to develop sustainable practices, ensure high quality, and out-deliver the competition.

A pivotal component of modern manufacturing is computer-aided engineering (CAE). It utilizes advanced software tools to simulate and optimize different engineering processes. Many teams rely on it to help analyze design concepts and validate ideas before moving forward.

CAE integrates sophisticated computer technology to simplify design iteration. This advantage lets product developers pass through various production phases, enhancing efficiency and boosting precision. More precise outcomes with less waste are essential for sustainable manufacturing and cost-effective innovation.

Computer-aided engineering offers numerous benefits, enabling teams to create virtual prototypes or run simulations mimicking real-world scenarios. Rapid prototyping (RP) helps improve product performance, durability, and manufacturability. CAE is the collaborative tool that makes it possible.

FACT: Computer-aided engineering tools allow remote collaboration to minimize product failure risk, shorten development cycles, and reduce iteration costs.

Table of Contents

Understanding the Core Concepts of Computer-Aided Engineering

CAE Design and Optimization Capabilities

Visualization and Virtual Prototyping

The Intersection of Computer-Aided Engineering and Rapid Prototyping

Benefits of CAE in Rapid Prototyping

Real-world Applications of CAE in Rapid Prototyping

Healthcare and Biomedical Engineering

Challenges in Integrating CAE with Rapid Prototyping

Data Accuracy and Reliability in Computer-Aided Engineering

Understanding the Core Concepts of Computer-Aided Engineering

Innovative engineers use computer-aided engineering (CAE) to leverage advanced visualization techniques for predictive analysis. Examples are Finite Element Analysis (FEA), Computational Fluid Dynamics (CFD), and Multibody Dynamics (MBD). These simulations allow innovators to determine component behavior in various circumstances without requiring a physical mockup.

The core concepts encompass structural analysis, thermal dynamics, material properties, and electromagnetic interactions. Teams that master optimization techniques and integrate computer-aided design (CAD) enjoy efficient methods, accurate and practical results, collaborative tools, and High-Performance Computing (HPC) advantages.

Proficiency in CAD and CAE means smoother design refinements, accelerated development cycles, and enhanced product reliability across multiple industries. Let’s zoom in on FEA, CFD, and MBD for a better understanding:

We offer fast, high-quality, tailored PROTOTYPING solutions for leading companies in a wide range of industries.

superior Rapid PROTOTYPING

Finite Element Analysis

Use FEA to predict how structures and systems behave with different features under tailorable conditions. Break complex designs into miniature elements to calculate stress, strain, and other key performance indicators (KPIs). Then, improve the geometry to ensure structural integrity for diverse distribution.

Computational Fluid Dynamics

Use CFD to model fluid flow, heat transfer, or energy usage. Computational fluid dynamics predict aerodynamics and combustion to help create efficient or sustainable systems. This core component of computer-aided engineering plays a pivotal role in aerospace, automotive, and medical manufacturing.

Multibody Dynamics

Use MBD to simulate motion between interconnected bodies. Engineers rely on multibody dynamics when designing mechanical systems, machinery, vehicles, and aircraft. This CAE tool ensures precision and optimal performance despite unconventional features.

Discuss which computer-aided engineering core concepts best suit your project with a rapid prototyping expert. Choose techniques that help you catch errors and take products to market faster.

CAE Design and Optimization Capabilities

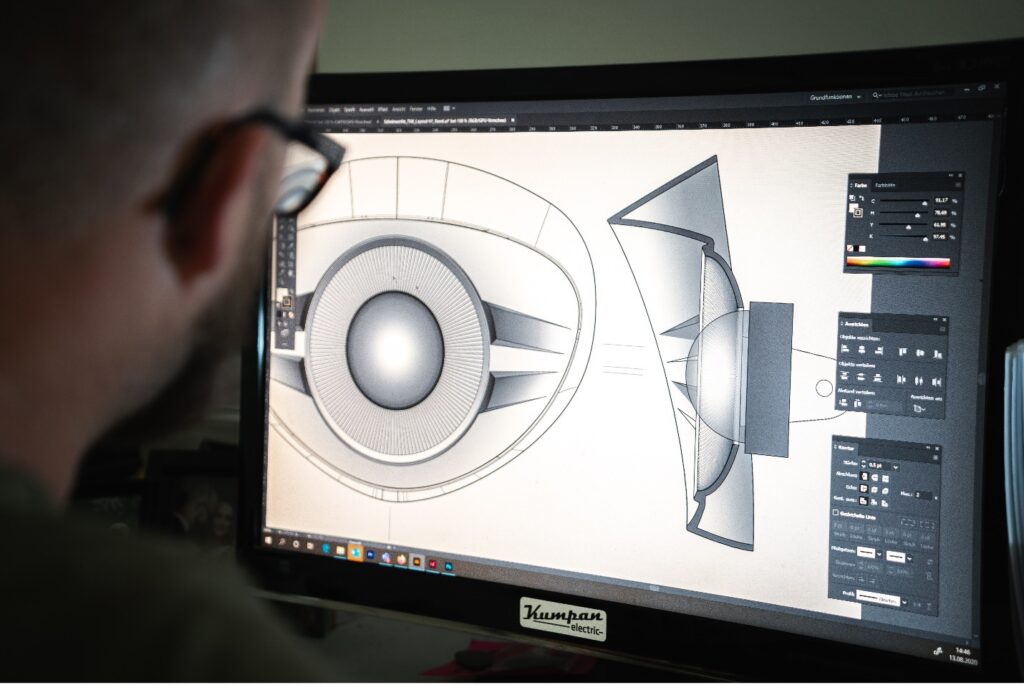

Advanced CAE techniques have transformed methodologies like generative design and topology op. Product development, iteration, and validation depend on computational tools and algorithms to explore vast spaces efficiently. Computer-aided engineering challenges conventional paradigms to foster creativity across all engineering phases without excessive waste.

While CAE methodologies offer substantial advantages for entrepreneurs, they also demand intuitive interpretation and refinement. Rapid prototyping ensures outcomes align with manufacturing feasibility, material availability, and other practical constraints. Therefore, computer-aided engineering is about more than determining how groundbreaking your concepts are. It is a fundamental part of a comprehensive process.

Take generative design, for example. It considers novel shapes and configurations that human designers might not conceive. GD helps teams innovate efficiently with inorganic forms, lightweight but stable structures, and products with improved appearance or functionality. Meanwhile, topology optimization is a subset of generative design that helps distribute materials within a given space for top performance. These CAE capabilities are imperative to automotive, aerospace, agriculture, food production, and more.

Visualization and Virtual Prototyping

Part of product optimization is visualizing details or watching designs in action. However, creating physical prototypes for each iteration can be too costly. Computer-aided engineering uses money-saving tools like 3D printing, augmented reality (AR), virtual reality (VR), artificial intelligence (AI), and machine learning. Advanced CAE instruments minimize design risks with rapid prototyping services tailored to project goals.

Explore multiple concepts quickly, simulate behaviors, analyze performance, and optimize for a competitive edge. However, understand that computer-aided engineering requires accurate data, sharp programming skills, and interpretation competencies to extract meaningful insights.

The Intersection of Computer-Aided Engineering and Rapid Prototyping

What is the rapid prototyping definition, and how does it intersect with computer-aided engineering? Furthermore, what does the evolution of RP look like after the advent of CAE? This section will explore the answers.

Rapid prototyping (RP) is a swift creation process for making physical prototypes using additive manufacturing (3D printing) technologies. It relies heavily on computer-aided design (CAD) software to align input with output. Engineers can transform digital mockups into tangible models using sustainable materials and non-subtractive manufacturing to save time and money without compromising quality.

RP in CAE fosters innovation and supports accurate functional testing. However, it wasn’t always this way. Computer-aided engineering has significantly influenced the evolution of rapid prototyping in modern manufacturing. Engineers can simulate, visualize, collaborate, optimize, and test features before printing or fabricating them. These symbiotic technologies bridge the gap between digital design and physical ingenuity.

FACT: You can gather data-based insights about structural integrity, thermal dynamics, material behavior, and more with rapid prototyping empowered by CAE.

Benefits of CAE in Rapid Prototyping

Integrating computer-aided engineering in rapid prototyping offers compelling benefits to help reshape product development processes. It also expedites crucial phases by decreasing teams’ reliance on physical models for validation and demonstration. Experts can also identify flaws more easily, analyzing stress points while producing rapid feedback loops for consideration.

Modify features based on CAE analysis results, then implement changes accordingly without starting from scratch. Align prototypes more closely with desired outcomes, streamline product development timelines, and cut costs associated with multiple iterations. Meet or exceed industry expectations with advanced manufacturing technologies.

Computer-aided engineering and rapid prototyping are a boon for sustainability advocacy. Teams can avoid expensive errors and reduce the need for post-production modifications by integrating CAE and RP. This benefit helps eliminate unnecessary material waste, energy consumption, and labor requirements. It can also help those in highly regulated industries comply with specific obligations.

Real-world Applications of CAE in Rapid Prototyping

The practical applications of rapid prototyping in computer-aided engineering are pervasive, notably in automotive design, aerospace and defense, consumer electronics, and healthcare and biomedical engineering. It enables virtual crash tests, ensures safety, and supports energy-efficient concepts.

Look at the vehicle development process. RP and CAE allow engineers to enhance fuel efficiency and reduce drag with durable, lightweight components that perform well under pressure. They can use CAE to simulate aerodynamics and determine optimal body shapes, then switch to RP to develop models for testing or final products for distribution with 3D printing technology.

Aerospace and Defense

Computer-aided engineering in rapid prototyping has revolutionized the aerospace and defense sectors. The combination provides tools for thorough stress tests, thermal simulations on aircraft components, and operational conditions analyses of structural integrity in extreme environments.

Consumer Electronics

CAE simulations can model heat dissipation and distribution within consumer electronic components to ensure safe operating temperatures. RP, 3D printing, and other digital fabrication processes can help enhance product durability while keeping the costs of high-quality products affordable.

Healthcare and Biomedical Engineering

Innovative teams use computer-aided engineering to simulate biomechanics and medical device performance. CAE enables biological 3D tissue modeling to determine crucial behavior indicators when interacting with various materials or designs. These techniques are essential for creating safe implants, prosthetics, and surgical tools.

Experts know that computer-aided engineering and rapid prototyping provide critical data for making informed decisions. They use an integrated manufacturing approach to contribute to advancements in their industry. CAE in RP improves consumer satisfaction, boosts user experience, and increases the buyer’s quality of life.

Computer-aided engineering (CAE), computer-aided design (CAD), rapid prototyping (RP), and 3D printing are complex tools requiring specific skills and equipment. Although multiple industries utilize them, maximizing their potential means programming and operating sophisticated software and machinery. Discuss the options with a manufacturer experienced in digital fabrication techniques.

Challenges in Integrating CAE with Rapid Prototyping

Unfortunately, blending computer-aided engineering techniques with rapid prototyping means encountering multiple challenges. For example, the complexity of advanced simulations can present steep learning curves for inexperienced teams. Others could require high-performance computing to handle simulations but deal with hardware limitations, data accuracy, and information availability issues.

Ensuring clean, reliable, and consistent data for CAE is another challenge. Also, some teams struggle with software algorithms and solver instabilities. Computer-aided engineering and CAD tools have matured significantly, but unforeseen problems, numerical inconsistencies, and convergence issues can still arise.

Engineers must test and validate the software itself to enhance reliability. Meanwhile, utilizing sophisticated tools like Computational Fluid Dynamics (CFD) and Finite Element Analysis (FEA) demands a profound understanding of manufacturing, software functionality, programming, and rapid prototyping technologies.

The steep learning curve can be a hurdle for innovators, necessitating unexpected training or hiring expertise. Engineers can’t rely solely on visual simulations but must comprehend the underlying physics, navigate model intricacies, consider boundary conditions, and accurately interpret results. Moreover, complex simulations require significant computational power not typically available outside advanced manufacturing facilities.

High-performance computing (HPC) poses hardware limitation challenges for intricate CAE simulation projects. Cost and accessibility can be barriers to entry for small organizations, entrepreneurs, and startups. Also, transitioning from traditional manufacturing to digital fabrication with computer-aided tools might require continued support and software updates for seamless integration and quality outcomes.

Data Accuracy and Reliability in Computer-Aided Engineering

CAE simulations depend heavily on precise data input with well-defined parameters. Any data discrepancies or inaccuracies can lead to questionable or unfavorable results. Engineers achieve precision by correlating simulation predictions with real-world indicators while considering setup phase conditions. They must also evaluate and integrate data involving material properties, boundaries, and load cases.

Since establishing confidence in CAE-generated data is vital, teams must validate simulation results against physical tests. Using rapid prototyping for this phase is wise. RP provides a powerful tool for product development by simplifying the usability of computer-aided engineering tools and helping inexperienced innovators overcome challenges.

Continuous advancements in software technology and hardware capabilities will improve collaboration and enhance future outcomes. The potential benefits of this integration make it a crucial endeavor for competitive industries. Strive to innovate and optimize with data-driven decision-making and advanced manufacturing techniques.

Conclusion

Computer-aided engineering has revolutionized rapid prototyping and sustainable manufacturing. It enables teams to simulate and optimize designs virtually before physical production. Although integrating digital fabrication technologies can create a steep learning curve for innovators, CAE and RP help develop safer, more efficient products.

Embracing complex simulation technologies like Finite Element Analysis (FEA) and Computational Fluid Dynamics (CFD) lets engineers predict behaviors, reduce iteration expenses, and enhance component quality. Computer-aided engineering and design in rapid prototyping make creativity more accessible across industry lines, resourcefully pushing boundaries to discover endless possibilities.

Discuss how CAE technologies in rapid prototyping with 3D printing can become your team’s catalyst for innovation. Then, learn how computer-aided engineering, CAD, and RP reshape the manufacturing landscape for a more sustainable future. Contact HLH Rapid for a comprehensive project quote, custom RP guide, and information about integrating CAE.

About the Author

About the Author

James Murphy is the founder and CEO of HLH Rapid – a hybrid CNC machine shop fusing Western service and quality with Eurasian industry influences for over 14 years. His advanced enterprise uncovers cost-effective rapid injection molding techniques to remain unmatched by industry competitors. Murphy’s full-service fabrication and manufacturing methods span six dedicated zones, from 3D printing and vacuum casting to sheet metal prototyping and project management. His expertise also includes high-efficiency machining within strict yet volatile markets.

Murphy earned an MBA after becoming inspired by his father’s hands-on craftsmanship. As a budding entrepreneur, he taught English and studied Chinese to pursue pioneering objectives. His groundbreaking approach helps build the future by providing well-rounded manufacturing services to innovative Western businesses. When he’s not offering upscale RP and CNC, James enjoys art-house movies, Thai boxing, and spending time with his growing family.

Visit HLHRapid.com for an instant quote on rapid prototyping services.