Aerospace prototyping plays an essential role in our economy. Innovative engineers must design and test parts before mass production. However, fabricating full-scale components is often too expensive for practical applications. Find out how rapid prototyping can help.

Aerospace prototyping helps support an ever-changing economy. It also ensures maximum safety and standardizes outcomes for global distribution. Rapid prototyping services allow aerospace engineers to develop innovative components without sacrificing quality or precision. However, those aren’t the only benefits.

Rapid prototyping means bringing new design concepts to life while cutting costs and reducing lead times. Aerospace prototyping allows for specialized production and customization, creating competitive parts and conserving materials. This article highlights the primary advantages of rapid prototyping for aerospace projects.

What is RP, and how does it relate to aerospace prototyping? Do the experts use specific techniques, or are you supposed to determine the methods? Here is what you need to know.

Table of Contents

Rapid Prototyping and the Aerospace Industry

Why Aerospace Needs Rapid Prototyping

Aerospace Prototyping Benefits

Tips for Using Aerospace Prototyping on Crucial Projects

TIP: Consider Your Prototype a Disposable Artifact

TIP: Focus on the Prototype’s Purposes Only

TIP: Test Interactions as You Go

Is Rapid Prototyping the Same as 3D Printing?

What Are the Pros and Cons of Aerospace Prototyping?

How Much Does Aerospace Prototyping Cost?

What Is Rapid Prototyping?

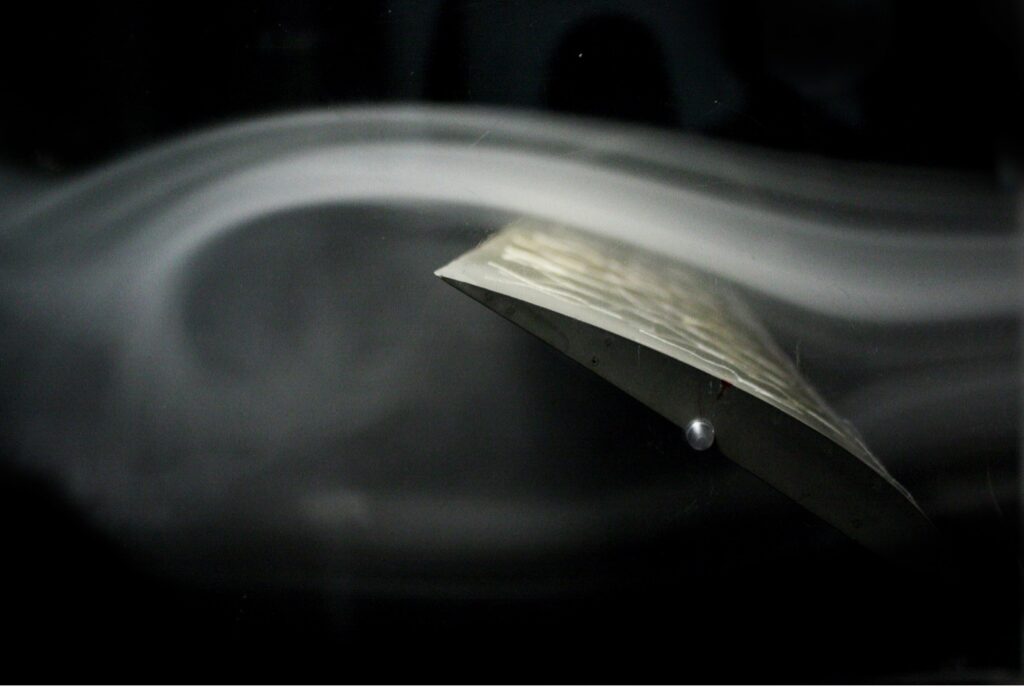

Aerospace engineers frequently produce scale models of various components to test their compatibility with other features. They often use rapid prototyping (RP) to develop a three-dimensional representation of different parts. RP is an umbrella term describing fast-paced fabrication techniques for examination. Designers typically recommend this phase before mass production.

Rapid prototyping can involve several processes, depending on the desired outcome. For example, some aerospace prototyping projects could include 3D printing, while others require simpler CNC machining. Most RP orders for aerospace engineers also follow highly regulated ISO standards for the industry. Therefore, fabricated parts represent the final design but are not appropriate for immediate installation.

Experts employ sophisticated manufacturing software to develop a computer-aided design. Then they program the specifications into their systems before running a series of operations to create the prototype. Engineers can adjust the features and change tolerances on-screen before production, saving time and resources for the final design.

The Purpose of the Prototype

Rapid prototyping has been around since the 1970s. Various industries use it to bring ideas from the mental realm into physical existence. High-tech methods help product developers make 2D sketches a 3D reality. Thus, aerospace prototyping is an essential service. Most other industries also rely on RP for efficiency.

Prototypes can serve multiple purposes, depending on the project goals. Rapid prototyping helps designers minimize risk and maximize profits while reducing product development costs. Engineering teams can observe processes, experiment with materials, change the design, and demonstrate alterations before committing to mass manufacturing.

DID YOU KNOW: You can save 10-20% of your production budget by creating 3D models with rapid prototyping.

We offer fast, high-quality, tailored PROTOTYPING solutions for leading companies in a wide range of industries.

superior Rapid PROTOTYPING

Rapid Prototyping and the Aerospace Industry

Aerospace prototyping accounts for a significant portion of the RP industry. Like many other sectors, engineers face unique challenges when developing new concepts. They must factor in technological limitations, manufacturing restrictions, lead times, and fabrication costs. Coordinating all those things for instant production may prove impossible without a troubleshooting phase.

The advancement of rapid prototyping in aerospace is evident and comforting. Aircraft engineers must adhere to significant regulatory requirements to meet industry demands. Exceeding consumer or industrial expectations is more challenging without aerospace prototyping. Meanwhile, cutting out the RP process can jeopardize some companies. They may end up developing useless designs.

Why Aerospace Needs Rapid Prototyping

The aerospace sector requires top-of-the-line performance for optimal efficiency and safety. Consumers, investors, and engineers depend on high-quality manufacturing to ensure peace of mind and meet industry standards. However, some components are more complex than others. Their inclusion in an existing blueprint could be troublesome without a dynamic design.

Rapid prototyping provides a middle ground for designers, developers, and engineers. They can swap ideas and improve various features to satisfy aeronautical objectives before signing off on any changes. Most aerospace prototyping companies also use cutting-edge technology and inexpensive materials to complete orders in record time.

FACT: Rapid prototyping is a fast fabrication service, meaning complex projects take 1-2 months to complete.

Aerospace Prototyping Benefits

Prototyping for aerospace comes with multiple advantages. It helps streamline fabrication and manufacturing while saving project managers money. However, those benefits only scratch the surface. Here is what else you gain from rapid prototyping:

#1. Freedom of Design

Aerospace prototyping gives aeronautical companies more freedom of design to develop off-the-wall concepts. They can experiment with various features and geometries while preserving their original vision.

#2. Inexpensive Experimenting

Experimentation can be expensive and time-consuming without rapid prototyping. However, RP provides a cost-effective technique for trying new things. Charge ahead of the competition without breaking the bank.

#3. Easy Development

Producing innovative parts for aerospace projects means thinking outside the box. Still, testing never before seen ideas can be challenging. Rapid prototyping helps simplify production, making originality more accessible.

#4. Cost-Effective Comparison

Aerospace engineers can create several models with rapid prototyping. Many use different outcomes to compare features and eliminate problems. Explore various avenues while preserving the bulk of the budget for the final design.

#5. Concept Testing

Prototyping for aerospace means obeying strict ISO regulations and industry standards. Yet, most engineers can’t conceptualize issues without live testing. Aerospace prototyping lets them see parts in action before manufacturing.

#6. Team Coordination

Rapid prototyping helps product developers and engineers work together more efficiently. The designers can create concepts and confirm various features. Engineers can then modify and optimize the performance without extra overhead.

#7. Timely Evaluation

Determine whether design concepts work with expedited RP services for aerospace projects. Get new ideas off the ground before competitors or ahead of industry changes. Invest in tooling and machining only after a thorough evaluation of the parts.

Aerospace product manufacturers can create multiple scale models of parts for assessment. Meanwhile, material restrictions don’t always impact their concepts. Rapid prototyping lets engineers play with different textiles for optimal results. For more information about the best materials for aerospace prototyping, consult your design team.

Tips for Using Aerospace Prototyping on Crucial Projects

The global aerospace industry is growing by leaps and bounds already. However, market experts project billions in increased revenue by the turn of the decade. Frugal manufacturers should hop on the aerospace prototyping bandwagon ahead of schedule to innovate and fabricate excellence.

There’s a significant difference between fabricating, manufacturing, and rapid prototyping. Fabrication involves making a component based on a final design. Manufacturing consists of assembling the fabricated parts to create a finished product. However, prototyping is the phase that comes first. Here is how to make the most of it:

TIP: Consider Your Prototype a Disposable Artifact

Aerospace prototypes are tools providing freedom, knowledge, and creativity. They are not marketable products or meant for distribution. Rapid prototyping offers a disposable example for examination and redesigning, so don’t fret about the insignificant features—design parts from start to finish without waiting on an engineer’s input.

Prototype-making for aerospace projects should produce critical feedback for design enhancements. Teams can create specific models based on objectives, alternatives, schedules, and budgets and troubleshoot issues before widespread testing.

TIP: Focus on the Prototype’s Purposes Only

The scope and scale of any project are crucial because they can impact many factors. However, rapid prototyping helps engineers simplify designs and streamline production. The size and durability of a project can determine costs and lead times.

Savvy designers consider the primary purpose of a prototype before making it. They also consider various screen requirements while assessing aesthetics, content, and code. Many aerospace prototyping projects are suited for sketchy mockups, but others might need full-color comps. Discuss options with a rapid prototyping expert for a custom plan.

TIP: Test Interactions as You Go

Rapid prototyping best practices suggest testing designs throughout the development process. Many aerospace engineers use this methodology to address concerns before they become troublesome. Teams can swiftly improve strategies by creating and recreating components using variable interactions.

Determining where the design went wrong is more challenging when teams forget to test along the way. Chasing bugs to enhance a component can also be expensive and time-consuming. Aerospace prototyping should be efficient and affordable, so check interactions while building to avoid excess and waste.

DID YOU KNOW: Many marketing companies use rapid prototyping to develop mockups of trending products for displays and advertising.

Rapid Prototyping FAQs

Aerospace engineering relies heavily on high-quality rapid prototyping services. However, the necessary processes can be too complex for DIY. They typically require expert tooling, CNC machining, and intuitive software programming. Cutting corners is unacceptable for ISO-regulated industries such as aerospace, automotive, and medical.

Rapid prototyping helps manufacturers pass inspections and become thought-leaders in their industries. Product designers and aeronautics masterminds should understand crucial facts before launching an RP project. Here is what they need to know:

Is Rapid Prototyping the Same as 3D Printing?

Three-dimensional printing is not the same as rapid prototyping. RP uses various techniques to produce scale models from a CAD file. Therefore, additive manufacturing is the fabrication process, and a prototype is an outcome. 3D printing sometimes involves rapid prototyping to make custom components, but not always.

We offer fast, high-quality, tailored PROTOTYPING solutions for leading companies in a wide range of industries.

superior Rapid PROTOTYPING

What Are the Pros and Cons of Aerospace Prototyping?

RP for the aerospace industry is essential, although not a perfect process. Teams can run into problems or miss deadlines because of several unpredictable factors. The worst thing an engineer can do is expect perfection instead of precision. While rapid prototyping can produce accurate renderings, results always depend on the techniques used.

Aerospace prototyping is also more expensive than model-making for other industries. The reason is that aeronautics generally require high-end materials and delicate manufacturing processes to satisfy ISO standards. RP can help reduce production costs and save time, but only under well-managed circumstances.

Engineers can still miss critical factors with an excellent prototype. Teams must collaborate in real-time to determine the viability of designs. Therefore, many crews keep a flat blueprint for discussions until the very last minute.

How Much Does Aerospace Prototyping Cost?

Rapid prototyping costs for aerospace projects can vary depending on the project, schedule, and materials. However, those aren’t the only factors in play. Here are the other things that can impact the price tag:

- Product Type

- Industry Regulations

- Design Stage

- Prototype Purpose

- Size and Volume

- Surface Finish

- Post-Manufacturing Maintenance

Calculate the cost of a prototype by considering the various stages involved. Each phase can incur special pricing based on your starting point and location.

- Concept Development – This is the research and decision-making phase. It’s imperative to the outcomes and can help dictate the budget. Bring foam models, 3D renderings, and user interface mockups to demonstrate ideas.

- Project Engineering – Teams will quantify and compare concepts to decide on the final design in this phase. Engineers can tailor results while maintaining a tight budget by providing feedback before processing.

- Prototype and Test – Things get interesting here because teams can see their concepts come to life. Functional alpha prototypes help display complexities, enhancements, and output before mass manufacturing.

- Setup Manufacturing – Here is when rapid prototyping takes a back seat to efficient fabrication. This early manufacturing stage helps mitigate costs and provides one last chance to alter the design before go time.

Aerospace prototyping doesn’t always require every phase, so discuss the options with an expert.

Conclusion

Rapid prototyping underpins the aerospace industry like many other sectors of our economy. It provides realistic scale models of complex designs for examination and approval. However, aerospace prototyping is not flawless, so engineers must know the pros and cons.

Aerospace engineers can benefit from RP in several ways, including cost reduction, time management, and ISO compliance. Meanwhile, rapid prototyping may require specific preparation steps that can impact project objectives. Discuss options and alternatives with an RP specialist to determine the best plan.

About the Author

About the Author

James Murphy is the founder and CEO of HLH Rapid – a hybrid CNC machine shop fusing Western service and quality with Eurasian industry influences for over 14 years. His advanced enterprise uncovers cost-effective rapid injection molding techniques to remain unmatched by industry competitors. Murphy’s full-service fabrication and manufacturing methods span six dedicated zones, from 3D printing and vacuum casting to sheet metal prototyping and project management. His expertise also includes high-efficiency machining within strict yet volatile markets.

Murphy earned an MBA after becoming inspired by his father’s hands-on craftsmanship. As a budding entrepreneur, he taught English and studied Chinese to pursue pioneering objectives. His groundbreaking approach helps build the future by providing well-rounded manufacturing services to innovative Western businesses. When he’s not offering upscale RP and CNC, James enjoys art-house movies, Thai boxing, and spending time with his growing family.