RP methods can vary depending on the goals. Some could cost more than others, and the outcomes are also different. Here are rapid prototyping methods for lower manufacturing costs and higher-quality products.

RP methodologies depend on tolerances, lead times, and budgets. Each project requires a different approach so that the outcomes can be unique. Custom machining is crucial in the modern economy, but affording rapid prototyping services can be tricky.

This article will discuss RP methods for lowering manufacturing costs without sacrificing quality. It will also review primary factors that can affect your fabrication price tag. Use this information to develop a cost-effective manufacturing strategy with rapid prototyping at the helm.

Table of Contents

The Importance of Rapid Prototyping

Factors That Affect RP Pricing

The Best Rapid Prototyping Methods for Tight Budgets

#1. Begin With Rudimentary Designs

#2. Integrate Automation Wherever Possible

#3. Use Different Material Grades

#4. Plan with Well-Connected Fabrication Shops

#5. Run Analytics to Determine the Focus Points

What Industries Use RP the Most?

What Are the Different Types of Rapid Prototyping?

Are There Any Disadvantages to RP?

What Is the Difference Between Additive Manufacturing and Rapid Prototyping?

Which RP Methods Can Use Metals?

The Importance of Rapid Prototyping

Rapid prototyping is essential to innovation, energy conservation, and cost-cutting across global markets. It helps ensure regulatory outcomes despite differing policies and expectations. RP also reduces shipping costs by eliminating unusable components from untested designs.

“Manufacturers can confidently fabricate and distribute intricate pieces without deal-breaking flaws.”

RP underpins nearly every industry because of its practical application. Manufacturing companies, engineers, and product development teams use rapid prototyping to streamline production with affordable troubleshooting techniques. The chosen RP method can help experts determine the best design materials, geometries, and assembly specifications.

We offer fast, high-quality, tailored PROTOTYPING solutions for leading companies in a wide range of industries.

superior Rapid PROTOTYPING

The importance of rapid prototyping cannot be overstated. Most industries rely heavily on ISO guidelines to maintain product quality consistency. However, developing parts without RP means fabricating dysregulated parts with unpredictable variables. Those conditions can destroy your competitive edge and prevent teams from moving forward in their given fields.

Bake rapid prototyping costs into your manufacturing budget for the best results. Meanwhile, remember that RP pricing can vary depending on multiple factors. Some techniques cost more because of design intricacies and production complications. Other methodologies are less expensive but may require additional machining before distribution. Understand the pros and cons before developing your rapid prototyping strategy.

DID YOU KNOW: The average price of RP can range depending on how much the fabrication shop charges for rapid prototyping services.

Factors That Affect RP Pricing

The factors determining RP costs are similar across the board, meaning every industry deals with them.”

Teams can calculate rapid prototyping prices based on several criteria, including their budgets and productivity goals. Discuss options with your team to determine the most appropriate approach.

Still, frugal staff won’t always be able to avoid high processing fees because of the various factors that impact manufacturing costs. RP pricing is also tricky due to the multiple variables involved. Your original design might appear simple but require unexpected processing to form a usable part. Keep a balanced but flexible budget to avoid impossible circumstances.

Consult your team for a detailed analysis and to ask critical questions. Then focus on adaptability in these crucial areas:

- Design Complexity – More complex designs will likely cost more to fabricate. Start with the fundamentals, then build out as needed to save time and money.

- Material Properties – Some materials are more challenging to machine than others. Choose low-cost, high-quality textiles compatible with your design’s essential elements.

- End Use Intentions – Many prototypes are for demonstrating features before mass production. Consider your model’s primary purpose and manufacture it accordingly.

- Lead Time Restrictions – Complicated designs might require more time for processing—plan projects in advance to avoid unwanted delays and additional fees.

- Troubleshooting Requirements – You can use RP to test different concepts and improve existing designs. However, repetitive rapid prototyping can get expensive.

Some products or parts might also have to be inspected for ISO standards compliance. This extra step usually increases the price of RP and can extend lead times. Learn ways to cut costs without sacrificing quality or falling behind the competition.

The Best Rapid Prototyping Methods for Tight Budgets

Some engineers avoid rapid prototyping because they think it costs too much. A few also assume it’s an unnecessary manufacturing step. However, companies that design new products with RP enjoy multiple benefits, including these:

- Increased brand recognition

- Better sales

- Fewer returns

- Improved product functionality

- Boosted industry authority

- Happier customers

RP is essential regardless of your industry, and it’s crucial even when designing minor parts. Tiny mistakes can pose a tremendous threat to your overall product’s efficiency, safety, and performance. Meanwhile, incorrectly manufactured parts can lead to costly and embarrassing recalls that break stakeholder trust.

Integrating rapid prototyping into your manufacturing budget is wise, even if you don’t have much extra money to spend.

“The benefits of RP could pay for themselves through bolstered consumer interest or dependence.”

Here is how to make the most of every dollar:

#1. Begin With Rudimentary Designs

You don’t have to develop a finished product unless that’s your prototype’s purpose. Often, it’s not. Most engineering teams use RP to design and fabricate individual components rather than complex assemblies. Then they combine the new parts with existing structures for testing and evaluation.

Begin with the most fundamental elements, troubleshooting various features along the way. Many fabrication shops will let you decide which aspects to focus on first. However, most also provide trained engineers to help you determine a comprehensive and advantageous approach.

TIP: Discuss your project goals with the engineering team for improved outcomes.

#2. Integrate Automation Wherever Possible

Machining automation is revolutionizing the manufacturing industry. It helps eliminate human error and expedites monotonous activities. Automated RP is also perfect for protecting workers from risky environments. This can help cut labor costs and reduce on-site safety or security expenses.

A fabrication shop with fewer liabilities is more likely to charge less for RP services. That means manufacturing automation can ensure top quality without costing top prices. Talk to your team to determine which processes you can automate for better efficiency.

TIP: Specific automated processes can help ensure the proper form, fit, and function ratio.

We offer fast, high-quality, tailored PROTOTYPING solutions for leading companies in a wide range of industries.

superior Rapid PROTOTYPING

#3. Use Different Material Grades

Know what to expect when selecting your materials for RP. Some machining materials can cost more to fabricate than others. Also, many options can require exporting, shipping, or special processing to use in your design. That’s why the most commonly used textiles are as follows:

- Silicone

- Glass Fiber

- Carbon Fiber

- Thermoplastics

- Stainless Steel

- Aluminum

- Raw Metals

- Wood

Meanwhile, each material listed comes in various grades with unique properties. They also feature inescapable pros and cons you should always consider.

“Work with a reputable RP shop for the best advice. Then look for superior materials with an excellent combination of machinability and strength.”

TIP: Choose versatile materials from a reliable supply chain to avoid expensive taxes and fees.

#4. Plan with Well-Connected Fabrication Shops

Find a consistent supply chain through an established fabrication shop with multiple sources. That way, you can choose between different vendors for the best prices. Competitive suppliers might also offer discounts to project managers who regularly order to buy materials in bulk.

Well-connected shops providing RP services can advise you on the pros and cons of each option. They can warn you when something threatens the supply chain and offer cost-effective alternatives to procuring your materials. This can help keep production rates high and rapid prototyping prices low.

TIP: Expect additional costs from overseas material suppliers and international vendors.

#5. Run Analytics to Determine the Focus Points

Rapid prototyping involves sophisticated software that can help teams analyze data and quickly integrate new information. RP experts use various tools for wireframing, brainstorming, and creating multi-use templates. Some software also lets teams collaborate and swap feedback for faster analysis.

Explore different concepts and share ideas while planning innovations and managing improvements. Then use read-to-use journey maps and flow charts to track progress and catch design mistakes in real-time. You can also utilize various analytical tools for planning your RP projects.

TIP: Compare different rapid prototyping software to determine a suitable match.

RP costs are variable depending on multiple factors, and some of those factors can change throughout the process. That’s because engineers discover several details while creating a high-quality prototype. Discuss those variables with your team to prevent avoidable hiccups and budget concerns. Also, ask questions for clarification and request an instant project quote.

RP Pricing FAQs

Determining RP prices can be tricky with several factors involved. You must inquire about the variables before launching a new project.

“Many fabrication facilities remain fully booked year-round, meaning lead times could get extended if you don’t appropriately plan.”

Meanwhile, expedited orders can cost more than your budget allows.

Request a consultation with your team and the fab shop handling your order. Then take notes to ensure clear communication with everyone. These are the most commonly asked questions about RP and the factors that can affect rapid prototyping costs:

What Industries Use RP the Most?

Rapid prototyping is helpful for nearly every industry. However, the industries most likely to use or depend on RP include the following:

- Healthcare

- Transportation

- Technology

- Communications

- Infrastructure

- Aerospace

- Automotive

- Consumer Goods

- Agriculture

- Manufacturing

Medical professionals need RP to develop better life-saving tools. Automotive and aerospace engineers rely on rapid prototyping to innovate for future sustainability. The other industries require RP to comply with ISO standards and integrate into demanding markets. Each sector produces enhanced goods and services to elevate economies and better serve communities.

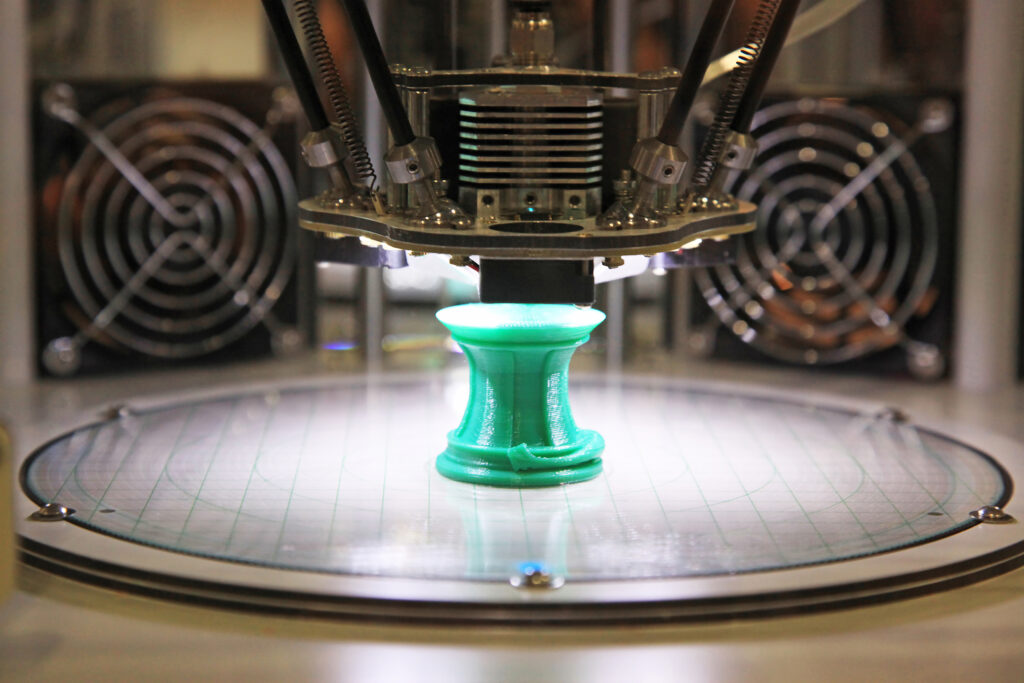

What Are the Different Types of Rapid Prototyping?

RP started as a rudimentary way to model parts or products for examination. However, today’s methods are much more refined and can handle exciting design concepts. There are multiple rapid prototyping technologies to consider, including these:

- Additive Manufacturing (3D Printing)

- Fused Deposition Modelling (FDM)

- Stereolithography (SLA)

- Direct Metal Laser Sintering (DMLS)

- Selective Laser Sintering (SLS)

- Binder Jetting

- Poly Jetting

Ask your team for more details on each RP technique. Decide which approaches cost more or less based on your project goals. Then adjust your budget and timeline to accommodate the highest quality outcomes.

Are There Any Disadvantages to RP?

Rapid prototyping can provide countless benefits for engineering teams and product developers. For example, it can help eliminate costly mistakes before market distribution. However, there are a few cons also to consider:

- Some models can be expensive to fabricate regardless of your RP method.

- Many software programs struggle to document details because of multiple design adjustments.

- There might be numerous requirement variations for each part.

- Excellent prototypes can cause increased consumer demand and industry competition.

- Rapid prototyping success does not equal mass manufacturing success.

Discuss the pros and cons with your team to develop a comprehensive and cost-effective strategy. Then decide which elements or processes to include or exclude from your plan.

What Is the Difference Between Additive Manufacturing and Rapid Prototyping?

Many people use RP and 3D printing interchangeably. However, rapid prototyping and additive manufacturing are two different processes. RP is a fabrication technique used to create models from a CAD file. Therefore, 3D printing is the procedure, and rapid prototyping is the result.

Which RP Methods Can Use Metals?

You can use various metals in RP if you use the correct method. For example, Direct Metal Laser Sintering (DMLS) is the most appropriate choice. This approach gives you high-quality three-dimensional metal prototypes without a long wait. However, it also costs more than other rapid prototyping techniques and could take as many as four weeks to complete.

Conclusion

RP expense reduction tips are vital for frugal manufacturing. They can help save teams time and money with a more efficient approach. Use wise fabrication strategies to cut costs while reaping the many benefits of rapid prototyping. You can decide on materials and timelines with more details.

Rapid prototyping methods can vary depending on several factors, including your goals and budget. Some approaches can cost more than others, and the outcomes are also unique. Choose the best RP techniques for lower prices and higher quality.

About the Author

About the Author

James Murphy is the founder and CEO of HLH Rapid – a hybrid CNC machine shop fusing Western service and quality with Eurasian industry influences for over 14 years. His advanced enterprise uncovers cost-effective rapid injection molding techniques to remain unmatched by industry competitors. Murphy’s full-service fabrication and manufacturing methods span six dedicated zones, from 3D printing and vacuum casting to sheet metal prototyping and project management. His expertise also includes high-efficiency machining within strict yet volatile markets.

Murphy earned an MBA after becoming inspired by his father’s hands-on craftsmanship. As a budding entrepreneur, he taught English and studied Chinese to pursue pioneering objectives. His groundbreaking approach helps build the future by providing well-rounded manufacturing services to innovative Western businesses. When he’s not offering upscale RP and CNC, James enjoys art-house movies, Thai boxing, and spending time with his growing family.

For more information or an instant quote on RP services, visit HLHRapid.com.