Automotive prototyping is essential to vehicular innovation. It allows product designers to adjust and examine various concepts before manufacturing. Meanwhile, rapid prototyping reduces waste, cuts lead times, and helps boost productivity. Here is what else you should know.

Automotive prototyping helps uphold an entire industry. It also ensures streamlined innovation, cost-effective production, and eco-friendly manufacturing. Project developers not using rapid prototyping risk missing opportunities to become more competitive.

Understanding complex designs is essential to every member of the team. However, many parts require a more comprehensive examination to determine relevance. RP lets the crew evaluate and troubleshoot ideas before mass manufacturing, implementation, inspection, or distribution. This advantage can help save them and their clients more than money.

How can the automotive industry benefit from rapid prototyping, and how does RP help the environment? Let’s explore the details to find out.

Title

Automotive Prototyping Overview

Rapid Prototyping for Automotive Eco-Innovation

Automotive Prototyping for Increased Safety Standards

What Are the Best Automotive Prototyping Methods?

Five Ways Automotive Prototyping Leads to Eco-Innovation

#1. Speedy Production

#2. Cost Reduction

#3. Diligent Digitization

#4. Increased Part Precision

#5. Tooling Durability

How to Take Advantage of Automotive Prototyping

Conclusion

Automotive Prototyping Overview

Automotive prototyping is a rapid prototyping method focusing on vehicular parts and components. It’s a complex process involving several steps, usually directed by an RP expert. Teams can determine their goals and schedule and then use rapid prototyping to develop innovative outcomes.

Product designers often prefer rapid prototyping to blind production. The reason is that rapid prototyping helps reveal design flaws before implementation. Crews can also troubleshoot various aspects of their design based on goals and budget restrictions.

“Automotive prototyping helps ensure stress-free inspections and compliance with industry standards.”

ISO places specific requirements on the automotive industry to guarantee safety and efficiency. However, the same measure of safety and efficiency isn’t always translated into the production of automotive components. Rapid prototyping provides a rough framework for careful considerations, giving teams the time and resources needed to innovate effectively.

Today’s customers demand more eco-friendly inventions from the automotive industry. However, this trend could cause unpredictable challenges for manufacturers and brands unwilling to embrace change. Corporations also assume more significant risks by purchasing parts not manufactured with RP. Therefore, automotive prototyping helps businesses test ideas and reduce liability across multiple sectors.

DID YOU KNOW: Automotive manufacturing produces parts that pass strict ISO regulations for standardized quality.

Rapid Prototyping for Automotive Eco-Innovation

Rapid prototyping for the automotive industry is crucial for countless reasons. First, automotive prototyping helps ensure fast results with minimal production costs. This allows teams to align their goals with budget limitations and market expectations. RP also helps companies outperform their competitors despite evolving ecological demands.

Exceptional market performance can lead to more attention from investors, stakeholders, and suppliers. Interested entities notice the enhancements from rapid prototyping because of the outstanding product quality. This also encourages improved partnerships through reduced financial and technical risks. Designers feel more confident innovating, while buyers feel assured about their savvy acquisitions.

Automotive prototypes are also suitable for demonstrations and examinations. Teams can reveal game-changing concepts to attract investors and gain momentum in a competitive industry. Test ideas and evaluate designs at trade shows for real-time feedback.

“Gather insights without incurring a loss or giving away precious trade secrets.”

Most likely, the competition is already ten steps ahead.

All automobile manufacturers attempt to orchestrate a fast and efficient assembly line. However, none want to sacrifice quality or safety to get it. Rapid prototyping provides eco-adaptability because it allows product designers to quickly exchange one component for another without producing excessive waste. Also, many RP processes utilize recyclable materials to reduce the carbon footprint further.

Automotive Prototyping for Increased Safety Standards

Manufacturers making car parts have an enormous responsibility to the public, not just the environment. They must carefully craft components that meet or exceed safety standards for the industry. However, that can be easier said than done, especially when incorporating innovative concepts.

Vehicle parts must have zero errors before distribution or implementation. Yet, manufacturing flawless designs is virtually impossible without rapid prototyping. For example, many product development teams employ scene mapping to review and evaluate the features of an automobile accident. Automotive prototyping helps increase product safety by exposing various parts to controlled environments for examination. If the team finds fault in the design under specific circumstances, they can rework it quickly.

Automotive prototyping uses various technologies and techniques to render precision outcomes despite the design complexities. Experts can also transfer the specifications to draft a functional model customized to the audience’s interests. Ask your team what’s possible for your project since each is unique, and flexibility is vital.

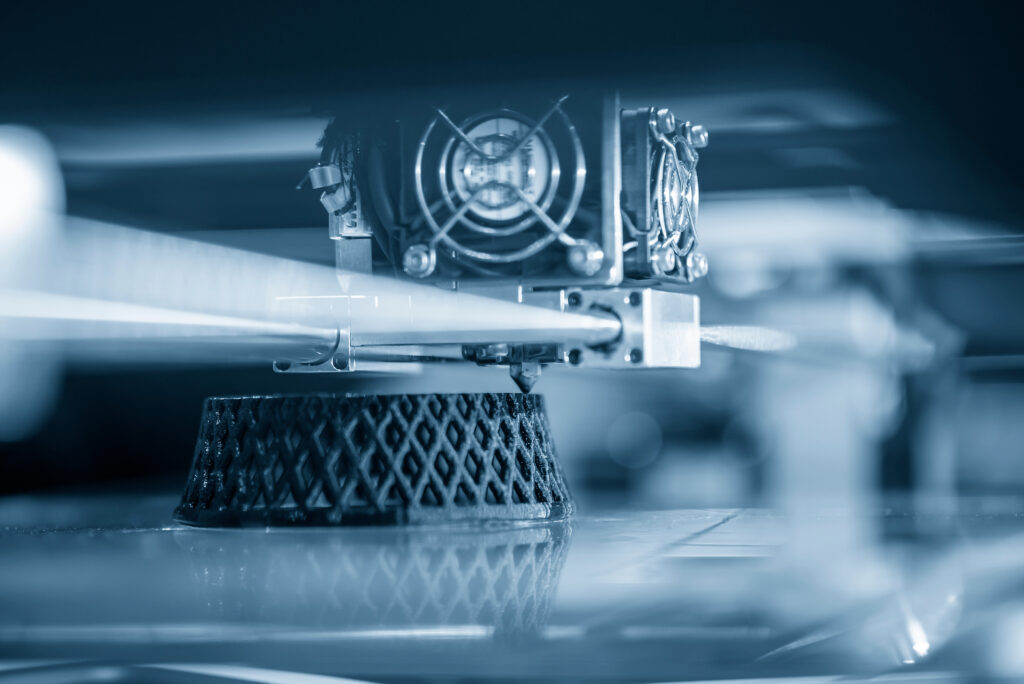

FACT: Automotive prototyping equipment typically includes 3D printers, conceptual modeling machines, and desktop software.

We offer fast, high-quality, tailored PROTOTYPING solutions for leading companies in a wide range of industries.

superior Rapid PROTOTYPING

What Are the Best Automotive Prototyping Methods?

Why is rapid prototyping such a boon for the automotive industry? Which RP methods are most helpful for making safe and eco-friendly car parts? Each project will require a different approach, but these are some of the standard techniques:

- CNC Machining – Involves using an automated milling machine to fabricate precision parts without direct human interaction.

- Soft Tooling – This uses a silicone rubber cast to create a repeatable mold for low-volume production.

- Additive Manufacturing – A complex 3D printing machine is used to create prototypes and models for further development and testing.

Automotive prototyping should allow manufacturers to examine and evaluate new product behavior under various conditions. However, they must partner with an adept service provider to ensure consistency and test relevance.

Five Ways Automotive Prototyping Leads to Eco-Innovation

Eco-innovation is one of the most talked about topics in today’s economy. Car companies strive to develop or obtain ecologically sound parts for their concerned consumers. Meanwhile, their competitors do the same thing, often introducing new concepts faster than their counterparts. This creates a competitive atmosphere that calls for rapid prototyping, 3D printing, and other efficient production methods.

Automotive prototyping ensures specific advantages for car manufacturers, distributors, dealerships, and buyers. It also promotes eco-friendly vehicle design concepts and encourages outcomes that push the industrial envelope. Here are five of the most apparent benefits of rapid prototyping for automotive manufacturing:

#1. Speedy Production

Rapid prototyping helps product development teams produce various parts for the same assembly. They can experiment with different concepts, try variable elements, and innovate quickly with advanced RP methodologies. Automotive prototyping can also simplify complicated procedures to enhance traditional manufacturing techniques.

Automotive prototyping means saving time on machinery setup and installation.

“Crews can develop functional models without utilizing heavy-duty or expensive tooling.”

Many car part manufacturers also offer fast and efficient 3D printing services to fulfill orders in only a few hours.

DID YOU KNOW: Rapid prototyping has helped increase the number of automobiles produced in every country.

#2. Cost Reduction

Automotive prototyping makes innovation less expensive, impacting our planet’s economy and ecological outlook. Buyers who spend fewer dollars on parts, labor, and distribution can allocate more capital for facility updates and procedural upgrades. In the meantime, their competitors will likely strive to do the same, causing a chain reaction that benefits everybody.

Manufacturers solely dependent upon traditional design techniques may fall behind the competition. Their operational and marketing costs could skyrocket if that happens. Automotive prototyping can help eliminate unnecessary expenditures while providing cost-effective solutions for industry demands. It also costs less to make a disposable model than an end-use product.

DID YOU KNOW: Much of the rapid prototyping process is automated to ensure precision and consistency.

#3. Diligent Digitization

Automotive prototyping involves measuring and manipulating numerical or digital values to produce a scale model. RP experts evaluate blueprints for design details and then use distinct strategies based on various factors such as:

- Materials

- Designs

- Tolerances

- Purposes

- Deadlines

- Audiences

Digitized prototyping helps teams coordinate evaluations, examinations, inspections, and presentations. Digital information is also more accessible and easier to manipulate for different outcomes without fudging the original design. This allows manufacturers to build the model in one location, transfer digital specifications to another site, test it, and then share the final concept once authenticated.

DID YOU KNOW: Many automotive manufacturers create 3D molds in-house before transmitting them to various locations via STL files.

We offer fast, high-quality, tailored PROTOTYPING solutions for leading companies in a wide range of industries.

superior Rapid PROTOTYPING

#4. Increased Part Precision

Precision is a non-negotiable feature for all automobile parts distributed to the global market. That’s why legitimate manufacturers obey ISO regulations for the industry. Close adherence to standardized practices helps ensure maximum acceptance from distributors, dealerships, investors, and consumers. It also means less waste and fewer trips to the repair shop.

Eco-friendly innovation typically involves fabricating parts made from reusable or sustainable materials. However, some traditional machining and manufacturing methods cannot compete with that. Automotive prototyping experts can tell you which textiles to use and where to offer tailored insights that help cut costs and reduce your carbon footprint.

DID YOU KNOW: Some countries have enacted policies that require automobile manufacturers to comply with eco-friendly regulations.

#5. Tooling Durability

Automotive prototyping leads to quickly manufactured parts, components, and assemblies with dimensional correctness. However, so does CNC machining. The difference is that rapid prototyping doesn’t require such durable tooling techniques and expended rigs. You can produce similar designs using digital data instead of objects that require shipping.

The tooling used for rapid prototyping is remarkable. Produce end products while achieving tighter tolerances than you could with traditional manufacturing methods. The production quantity is generally less, but you can produce significant quality rapidly and scale up as needed.

DID YOU KNOW: Tooling durability helps the global supply chain mitigate the effects of economic inflation on the automotive industry.

How to Take Advantage of Automotive Prototyping

Automotive prototyping brings several advantages and lowers production costs. This can help protect the global environment from the damaging effects of industrial innovation. However, you must harness its benefits to impact your bottom line. Here are some tips to get that done:

- Develop Your Design – Use the latest CAD software to illustrate your design concepts for mass distribution or comprehensive evaluation. Ask an expert if you need help.

- Incorporate Flexibility – Develop an idea that your teammates can examine and adjust according to the company goals and industry expectations.

- Choose Your Materials – Demonstrate readiness by selecting specific materials and testing their behavior in various scenarios. Adapt as needed.

- Build Your Budget – Leave room for minor changes and unexpected costs when using rapid prototyping to manufacture auto parts.

- Find Ways to Eco-Innovate – Discover new techniques and technologies for automotive prototyping. Lead the pack with your intelligent designs.

- Stay Abreast of the Latest Methods – Study the contest and keep your eye on the automotive manufacturing industry to ensure compliance and competitiveness.

“You can streamline automotive manufacturing by structuring your strategy around rapid prototyping.”

Then take advantage of the opportunity before others to control the trajectory of your brand and manage market upheavals without sacrificing product quality. Talk to an automotive prototyping expert for more information on tailoring the process to your objectives.

Conclusion

Automotive prototyping helps uphold the high standards of the automobile industry. It also reduces manufacturing waste, eliminates unnecessary costs, and renders usable components quicker than traditional techniques. Those concerned about the impact of vehicles on the environment should look more closely at this advanced technology.

Rapid prototyping for automotive designers can be tricky, with unique challenges at every stage. However, RP experts can help improve product outcomes through due diligence and comprehensive testing. Automotive prototypes often render improved designs with greater efficiency. This advantage can boost productivity, reduce lead times, and position car companies ahead of the competition.

Consult an RP specialist to discover how automotive prototyping can lead to more eco-friendly innovations. Determine your ideal outcomes, set your budget, and aim at an evolving industry with advanced manufacturing techniques.

About the Author

About the Author

James Murphy is the founder and CEO of HLH Rapid – a hybrid CNC machine shop fusing Western service and quality with Eurasian industry influences for over 14 years. His advanced enterprise uncovers cost-effective rapid injection molding techniques to remain unmatched by industry competitors. Murphy’s full-service fabrication and manufacturing methods span six dedicated zones, from 3D printing and vacuum casting to sheet metal prototyping and project management. His expertise also includes high-efficiency machining within strict yet volatile markets.

Murphy earned an MBA after becoming inspired by his father’s hands-on craftsmanship. As a budding entrepreneur, he taught English and studied Chinese to pursue pioneering objectives. His groundbreaking approach helps build the future by providing well-rounded manufacturing services to innovative Western businesses. When he’s not offering upscale RP and CNC, James enjoys art-house movies, Thai boxing, and spending time with his growing family.