3D printing, CNC machining, and rapid prototyping require high skill and experience to guarantee precision and repeatability. These intelligent manufacturing technologies help streamline production from every angle, giving countless industries the cutting-edge they need. Designers must follow these best practices to ensure optimal outcomes from their part designs.

3D printing is quickly becoming one of the most common manufacturing methods globally. It revolutionized the prototyping industry by providing a fast and accurate alternative to traditional model-making techniques. 3D printing is becoming a production choice, and 3D printed parts are everywhere; you’ll have encountered an additive manufactured part if you’ve ever seen a hearing aid or been in a car.

Countless industries rely on precision parts to ensure reliable products. This is especially true in the automotive, aerospace, and medical sectors. Parts must be fabricated based on strict ISO or other standards. That’s why it is essential for 3D printing to work towards standardization and implement best practices to move from prototyping to production and become even more valuable in today’s manufacturing supply chains.

What are the limitations of additive manufacturing? How do machine shops adhere to such stringent expectations? Is 3D printing ready to mass-produce products, or are we still in the prototyping phase? Here is what you need to know.

Table of Contents

Fused Filament Fabrication (FFF) or Fused Deposition Modeling (FDM)

What Is FDM 3D Printing Used For?

#1. Monitor Minimum Feature Size

#2. Account for FFF Alterations

#4. Manage Overhangs and Bridges

#7. Control Thermal Distortion

What Is 3D printing?

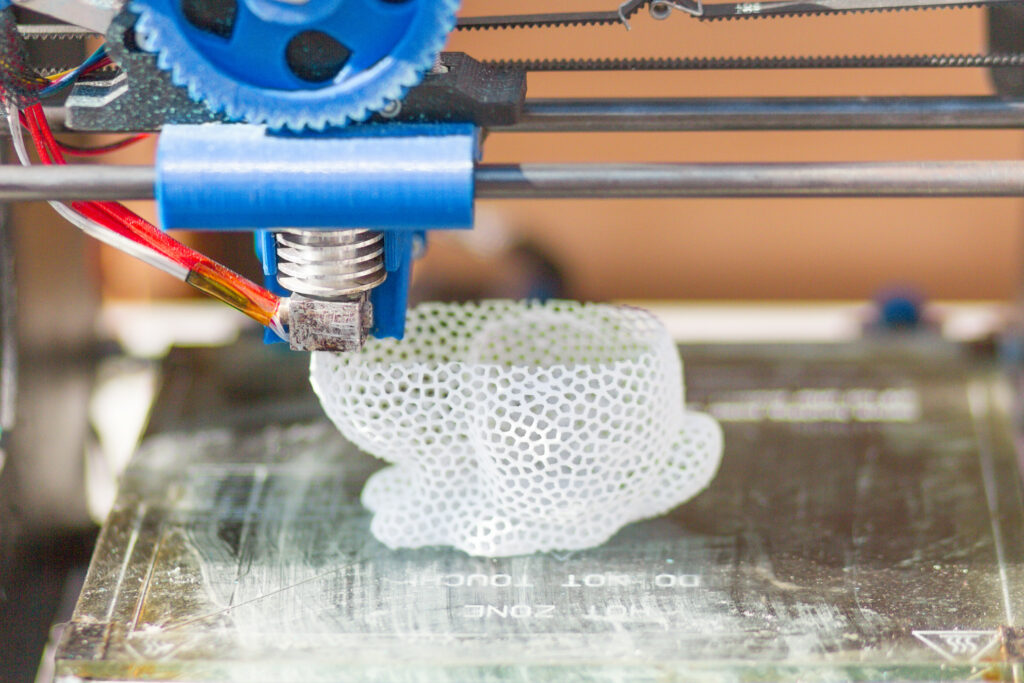

3D printing is another name for additive manufacturing (AM). The modern manufacturing process fabricates three-dimensional products by adding instead of subtracting material, hence the name “additive.” Unlike traditional part fabrication, this method does not remove mass from the workpiece to create various shapes. Instead, it builds parts layer by layer and can create highly complex shapes and geometries.

This complex manufacturing technique helps product designers create physical objects from digital blueprints or CAD files. It allows fast and accurate reproduction of the 3D CAD file, allowing designers to test new designs and concepts. Understanding how the process works and why best practices are essential can help you strategize better.

How Does FDM 3D Printing Work?

AM operators maintain precision through complex 3D printing process fundamentals. They also utilize industry best practices to ensure quality consistency and conformity to industry standards. This delicate technique lays down layers of molten material extruded through a print head. Parts are built layer by layer to form a proprietary shape according to the 3D CAD design.

Several different 3D printing processes and technologies exist, but one of the most common and widely utilized is FDM or fused filament fabrication. Let’s look more closely at it to understand better how 3D printing works.

Fused Filament Fabrication (FFF) or Fused Deposition Modelling (FDM)

Fused filament fabrication, or FFF, renders precision parts by printing layers of molten plastic into various geometries. As one of the most common AM processes, it is prized for its versatility and production integrity. Fused filament fabrication methods are also energy-efficient and often less costly than other manufacturing techniques. One of its significant advantages is the range of material choices available.

DID YOU KNOW: FFF or FDM is One of Many Cost-Effective Rapid Prototyping or RP Techniques.

NOTE: Most reputable CNC machine shops utilize FFF to provide low-cost RP services for AM customers.

We offer fast, high-quality, tailored PROTOTYPING solutions for leading companies in a wide range of industries.

superior Rapid PROTOTYPING

What Is FDM 3D Printing Used For?

Additive manufacturing offers multiple benefits with several use cases, especially when facilities respect best practices. 3D printing is versatile and utilized in numerous industries. service bureaus can also provide the following services via FDM and RP:

- Concept Modeling

- Small Run Production

- Fixture Fabrication

- Replacement Parts

- Rivet Manufacturing

- Tool Making

- prototyping

Through precision additive manufacturing, diligently crafted parts and components are available in different materials. Fabrication shops can use high-tolerance plastics, composite materials, synthetic rubbers, and machinable metals. Their work serves global economies and encourages revolutionary design ideas while reducing waste and cutting production costs.

3D Printing Best Practices

Following best practices for 3D printing means more than obeying strict ISO guidelines. While ISO ensures product consistency across multiple industries, it doesn’t account for all in-shop operations. The International Organization for Standardization is not in charge of design innovation or experimentation. It only pertains to specific fabrication operations and regulates distribution.

CNC machining and additive manufacturing rapid prototyping require extra due diligence to guarantee precision, repeatability, and safety. These intelligent methodologies help streamline production from every angle. This simplified fabrication technique gives countless industries the cutting-edge they need to remain competitive. Meanwhile, experts must follow these best practices to ensure optimal outcomes and practical applications.

#1. Monitor Minimum Feature Size

In additive manufacturing, geometry is essential. Accurate measurements mean favorable outcomes that function as intended. A 3D printer deposition is the smallest acceptable material deposit allowed by the machine. Additive manufacturing experts must know these numbers and adjust their approach as needed.

Material deposition dimensions are a critical component of 3D printing. The printer’s minimum feature size must equal the deposition size for error-free processing. Meanwhile, machinists approximate the parameters using a voxel system, a three-dimensional version of digital pixels.

3D-printed parts are essentially the sum of voxel sets. Therefore, experts can modify the design or troubleshoot various aspects before producing the entire object. Machine controls can then simplify material fusing for detailed inspection and rapid implementation.

#2. Account for FFF Alterations

Parts made with fused filament fabrication require a different set of standards. Extruder nozzles and Z-stage resolution limit the material deposition dimensions in this process. The nozzle size determines the lower deposition limit within the X-Y axes. However, the Z-axis resolution defines the deposition’s lower height measurements. Machinists must adjust for this when using FFF in 3D printing.

Most FFF 3D printers can fabricate precision parts with fluctuating layer heights. Still, experts must know the difference between high-quality and draft-quality outcomes. Generally, components made with thin material layers are showroom ready. Thick material layers are usually best for building first-round prototypes or simple scale models.

#3. Tweak Layer Thickness

Let’s say you print parts in thin layers of pliable material. In that case, you reap several benefits that aren’t available with thicker layering. For example, thinly layered 3D models render smoother finishes and are often more robust than their dense counterparts. This is due to the better fusing between the sheets.

Thin layering also helps keep parts waterproof and airtight. These components are typically perfect for aerospace, automotive, marine, and medical applications. However, thick layers don’t take as long to print. They might feature a rougher finish and less robust material fusion. Still, they’re practical for short-run projects and as visual aids.

DID YOU KNOW: Material layering and fusion can make or break your final design during an inspection. Thick layers might not suit strict industry requirements as functional prototypes or end-use components.

#4. Manage Overhangs and Bridges

FFF 3D printing consists of layering molten materials on top of one another. However, complex designs often create curves and edges that experts must handle manually. If the top or bottom layers don’t align perfectly, the final result could be disastrous. Misaligned layers can also fudge machine processing or confuse the CAD/CAM system responsible for directing tools.

Most 3D printers have overhang management features to help operators work more efficiently. For instance, machinists can utilize scaffold structures to print complicated geometries without messing up the final form. This helps reduce time spent, decrease waste, and satisfy ISO standards during the prototyping phase.

As for printing bridges, be prepared to fabricate layers over avoid. Operators might need dual scaffold structures to support the weight while layers print. However, advanced CNC machine shops usually have active part cooling printers to eliminate the need for external support.

#5. Ensure Part Strength

3D printing best practices involve checking the quality of fabricated parts. Components can look and feel terrific but still have asymmetries between the vertical and horizontal axes. Unfortunately, some of those flaws are challenging to detect with the naked eye. Machining experts must ensure part strength by testing the following things:

- Tensile Stress – Durability of the best vector paths within printed layers

- Shear Stress – Potency of printed parts with pressure applied to perpendicular layers

- Flexural Strength – Resilience to bending and applied force

Fabrication shops must also consider the infill density of 3D printed parts. This aspect involves the filling material between layers. Increased infill density usually means stronger, more durable outcomes. However, it can also mean increased printing time and production costs. Talk to your team for more details on balancing budgets with lead times.

#6. Check Tolerances

Accuracy is one of the best benefits of 3D printing. CNC machine shops using FFF printers typically offer tight tolerances, with a linear precision of .2-2%. Geometric exactitude means better fitting parts and more durable rivets. Experts can also design components and replicas to give interference fittings, clearance fittings, or transition fittings.

Additive manufacturing usually renders moderately oversized parts. Meanwhile, advanced three-dimensional fabrication software allows more intuitive control of the parameters. Enhanced geometric compensation means all components fit perfectly without changing multiple CAD specifications.

#7. Control Thermal Distortion

Thermal distortion is another 3D printing hazard mitigated by best practices. It’s most pervasive with FFF and rapid prototyping, although much CNC machining deals with it. Workpiece deformation depends on the materials, processes, and equipment. However, laying hot material over a cooled surface can have a widespread impact regardless of the approach.

Experts must follow stringent production guidelines to prevent material warping and thermal distortion. The layers can pull apart or lift from printed surfaces, compromising the durability and usability of parts. Without controlling thermal distortion, pieces can detach from the assembly and cost more to produce.

We offer fast, high-quality, tailored PROTOTYPING solutions for leading companies in a wide range of industries.

superior Rapid PROTOTYPING

3D Printing: Post Processing

Additive manufacturing is a near-net shaping process. That means it creates parts as close as possible to the original design. Still, some applications require additional surface finishing to achieve optimal results. This is called post-processing, and it plays a significant role in 3D printing best practices.

The additional manufacturing steps after initial processing are essential. They help regulate part consistency to ensure precision fittings with convenient lead times. Post-processing might increase fabrication costs or slow production, but the outcomes are usually worth the extra effort. Consumers and suppliers can always distinguish between rushed parts and precision machining.

Each project requires a specific approach to post-processing. However, the steps generally include the following:

- Support Structure Removal – Unclamping parts from supportive scaffolding using hands, pliers, or other tools like belt sanders and grinders

- Surface Finish Perfection – Mechanically smoothing parts with abrasive bead blasting, traditional sanding, brushing, coating, and dipping

- Coatings and Sealants – Covering the surface with clear or colored sealants using paint, dips, electroplating, or epoxy infiltration processes

- Assembly and Inspection – Gluing, welding, or otherwise bonding sections with conventional fasteners before testing their strength and adherence to industry standards

3D printing consists of numerous steps and a unique approach for each one. Machinists must also match the materials with the machining process to create practical outcomes that satisfy regulatory requirements. While additive manufacturing is not yet capable of large-scale handling projects and mass manufacturing, it continues to foster further innovation in CNC machining.

Benefits of AM, RP, AND FFF

Additive manufacturing, rapid prototyping, and fused filament fabrication go hand in hand. However, these production methods are not identical processes. Learn the differences between them to develop your manufacturing plans strategically.

Want to sound like a 3D printing expert? Remember, FFF is a type of AM used in RP and CNC. It’s versatile, cost-effective, and flexible enough to support ingenuity. Contact your machining team or look at examples for more details on the pros and cons.

Conclusion

3D printing, or additive manufacturing (AM), underpins many products in our modern economy. Developers strive for low-cost alternatives to traditional machining, discovering new ways to create better parts and assemblies. As one of the most versatile and convenient fabrication methods, three-dimensional printing relies on experts who follow best practices.

CNC best practices involve countless regulations, standards, and considerations. The reason is that fabricated parts must align with global distribution requirements. Create innovative components all day but fail to pass inspection without due diligence.

About the Author

About the Author

James Murphy is the founder and CEO of HLH Rapid – a hybrid CNC machine shop fusing Western service and quality with Eurasian industry influences for over 14 years. His advanced enterprise uncovers cost-effective rapid injection molding techniques to remain unmatched by industry competitors. Murphy’s full-service fabrication and manufacturing methods span six dedicated zones, from 3D printing and vacuum casting to sheet metal prototyping and project management. His expertise also includes high-efficiency machining within strict yet volatile markets.

Murphy earned an MBA after becoming inspired by his father’s hands-on craftsmanship. As a budding entrepreneur, he taught English and studied Chinese to pursue pioneering objectives. His groundbreaking approach helps build the future by providing well-rounded manufacturing services to innovative Western businesses. When he’s not offering upscale RP and CNC, James enjoys art-house movies, Thai boxing, and spending time with his growing family.